loading

| Availability: | |

|---|---|

| Quantity: | |

CYC-PVR01

CYC Energy

H-rail is a key component in the PV racking system, which is mainly used to fix and support solar panels. Compared with the traditional C-type and U-type rails, H-rails are widely used in the photovoltaic industry due to their unique cross-section design and structural advantages.

With the advantages of high rigidity, easy installation and long service life, H-rail has become the preferred solution for PV racking system, especially suitable for large modules, high wind pressure and harsh environment projects. With the demand for large-scale modules and cost reduction, its market penetration will continue to improve.

Feature:

Higher load-bearing capacity: H-rails have an "I" or "H" shaped cross-section, and the double-rib design (upper and lower flanges + center web) significantly improves flexural strength and rigidity.

Wind/snow resistance: better stability in areas with strong winds and snow, reducing the risk of module deformation or bracket collapse.

Installation convenience: Most H-rails have prefabricated mounting holes when shipped from the factory, which reduces the workload of on-site drilling and improves the construction efficiency.

Strong compatibility: Adaptable to a variety of pressure blocks and clamps (e.g., side-pressing, center-pressing type), and flexible to match different module frame types (framed/frameless).

Modular splicing: Quickly extend the length of the rail through connectors to adapt to complex terrain or customized layout requirements.

Corrosion Resistance and Long Life: Usually anodized aluminum or stainless steel is used for oxidation and salt spray resistance (suitable for coastal/high humidity areas).

Structural sealing: H-shape closed section reduces internal water and dust intrusion, extending service life.

| Installation location | Metal Roof |

| Installation angle | parallel |

| Applicable module type | Mono-crystalline, Poly-crystalline, Double wave and Thin film |

| Module Orientation | Horizontal, Vertical |

| Design standard | AS/NZS1170,JIS C 8955-2017,ASCE7-16 |

| Material | AL6005-T5,AL6005-T6 |

| Warranty&Duration | 15 years&More than 20 years |

Detailed Photo

H-rail is a key component in the PV racking system, which is mainly used to fix and support solar panels. Compared with the traditional C-type and U-type rails, H-rails are widely used in the photovoltaic industry due to their unique cross-section design and structural advantages.

With the advantages of high rigidity, easy installation and long service life, H-rail has become the preferred solution for PV racking system, especially suitable for large modules, high wind pressure and harsh environment projects. With the demand for large-scale modules and cost reduction, its market penetration will continue to improve.

Feature:

Higher load-bearing capacity: H-rails have an "I" or "H" shaped cross-section, and the double-rib design (upper and lower flanges + center web) significantly improves flexural strength and rigidity.

Wind/snow resistance: better stability in areas with strong winds and snow, reducing the risk of module deformation or bracket collapse.

Installation convenience: Most H-rails have prefabricated mounting holes when shipped from the factory, which reduces the workload of on-site drilling and improves the construction efficiency.

Strong compatibility: Adaptable to a variety of pressure blocks and clamps (e.g., side-pressing, center-pressing type), and flexible to match different module frame types (framed/frameless).

Modular splicing: Quickly extend the length of the rail through connectors to adapt to complex terrain or customized layout requirements.

Corrosion Resistance and Long Life: Usually anodized aluminum or stainless steel is used for oxidation and salt spray resistance (suitable for coastal/high humidity areas).

Structural sealing: H-shape closed section reduces internal water and dust intrusion, extending service life.

| Installation location | Metal Roof |

| Installation angle | parallel |

| Applicable module type | Mono-crystalline, Poly-crystalline, Double wave and Thin film |

| Module Orientation | Horizontal, Vertical |

| Design standard | AS/NZS1170,JIS C 8955-2017,ASCE7-16 |

| Material | AL6005-T5,AL6005-T6 |

| Warranty&Duration | 15 years&More than 20 years |

Detailed Photo

Xiamen CYC Energy Co., Ltd located in Xiamen city. Specialize in research, design, development, production, and service of Solar PV Mounting Systems. We are committed to providing customers with stable, reliable and cost-effective solutions of roof mounting system, ground mounting system, and construction of various photovoltaic power stations for civil and commercial use, government departments, power stations projects etc.

CYC energy company owns a factory with more than 15 skilled workers, having over 10 years solar products production experience. With a complete R& D processing and high manufacturing capacity, strictly following ISO9001 quality control system. Our products design strictly in accordance with Australia AS/NZS1170.2, JIS C 8955, MCS012, TUV, UL2703, European building codes and other standards. Ensure that every code and regulation is fully complied with all applicable local or national building codes. Cyc energy offering innovative design and integrative settlement solution to our customers based on years of experiences on design, production and sale.

We achieved good trust from customers because of our stable and excellent products. We will try our best to become a world leading level supplier of solar photovoltaic systems integration solutions.

Xiamen CYC Energy Co., Ltd located in Xiamen city. Specialize in research, design, development, production, and service of Solar PV Mounting Systems. We are committed to providing customers with stable, reliable and cost-effective solutions of roof mounting system, ground mounting system, and construction of various photovoltaic power stations for civil and commercial use, government departments, power stations projects etc.

CYC energy company owns a factory with more than 15 skilled workers, having over 10 years solar products production experience. With a complete R& D processing and high manufacturing capacity, strictly following ISO9001 quality control system. Our products design strictly in accordance with Australia AS/NZS1170.2, JIS C 8955, MCS012, TUV, UL2703, European building codes and other standards. Ensure that every code and regulation is fully complied with all applicable local or national building codes. Cyc energy offering innovative design and integrative settlement solution to our customers based on years of experiences on design, production and sale.

We achieved good trust from customers because of our stable and excellent products. We will try our best to become a world leading level supplier of solar photovoltaic systems integration solutions.

Production operation: Practical operation according to the production process, with a clear division of labor and production personnel operating strictly according to the operating procedures.

Quality control: Each production process has a quality check point for raw material inspection, process monitoring, semi-finished product testing, etc., to ensure that non-conforming products are detected and rejected in time.

Automation and monitoring: adopt automation equipment and information system for production process monitoring, real-time monitoring of production status, improve production efficiency and accuracy.

Finished Product Inspection: After production is completed, the product will undergo strict quality inspection to ensure that it meets the design requirements and quality standards. Common inspection items include dimensional accuracy, appearance, function test and so on.

Packaging: Products that have passed inspection will enter the packaging process. According to the product characteristics of the classification of packaging, and to ensure that the packaging materials comply with the standards, with sufficient protection.

Dispatch and delivery: Arrange for products to be discharged from the warehouse according to the customer's order, and use the appropriate logistics method for delivery. During the distribution process, distribution tracking will be carried out to ensure that customers receive the products in time.

Production operation: Practical operation according to the production process, with a clear division of labor and production personnel operating strictly according to the operating procedures.

Quality control: Each production process has a quality check point for raw material inspection, process monitoring, semi-finished product testing, etc., to ensure that non-conforming products are detected and rejected in time.

Automation and monitoring: adopt automation equipment and information system for production process monitoring, real-time monitoring of production status, improve production efficiency and accuracy.

Finished Product Inspection: After production is completed, the product will undergo strict quality inspection to ensure that it meets the design requirements and quality standards. Common inspection items include dimensional accuracy, appearance, function test and so on.

Packaging: Products that have passed inspection will enter the packaging process. According to the product characteristics of the classification of packaging, and to ensure that the packaging materials comply with the standards, with sufficient protection.

Dispatch and delivery: Arrange for products to be discharged from the warehouse according to the customer's order, and use the appropriate logistics method for delivery. During the distribution process, distribution tracking will be carried out to ensure that customers receive the products in time.

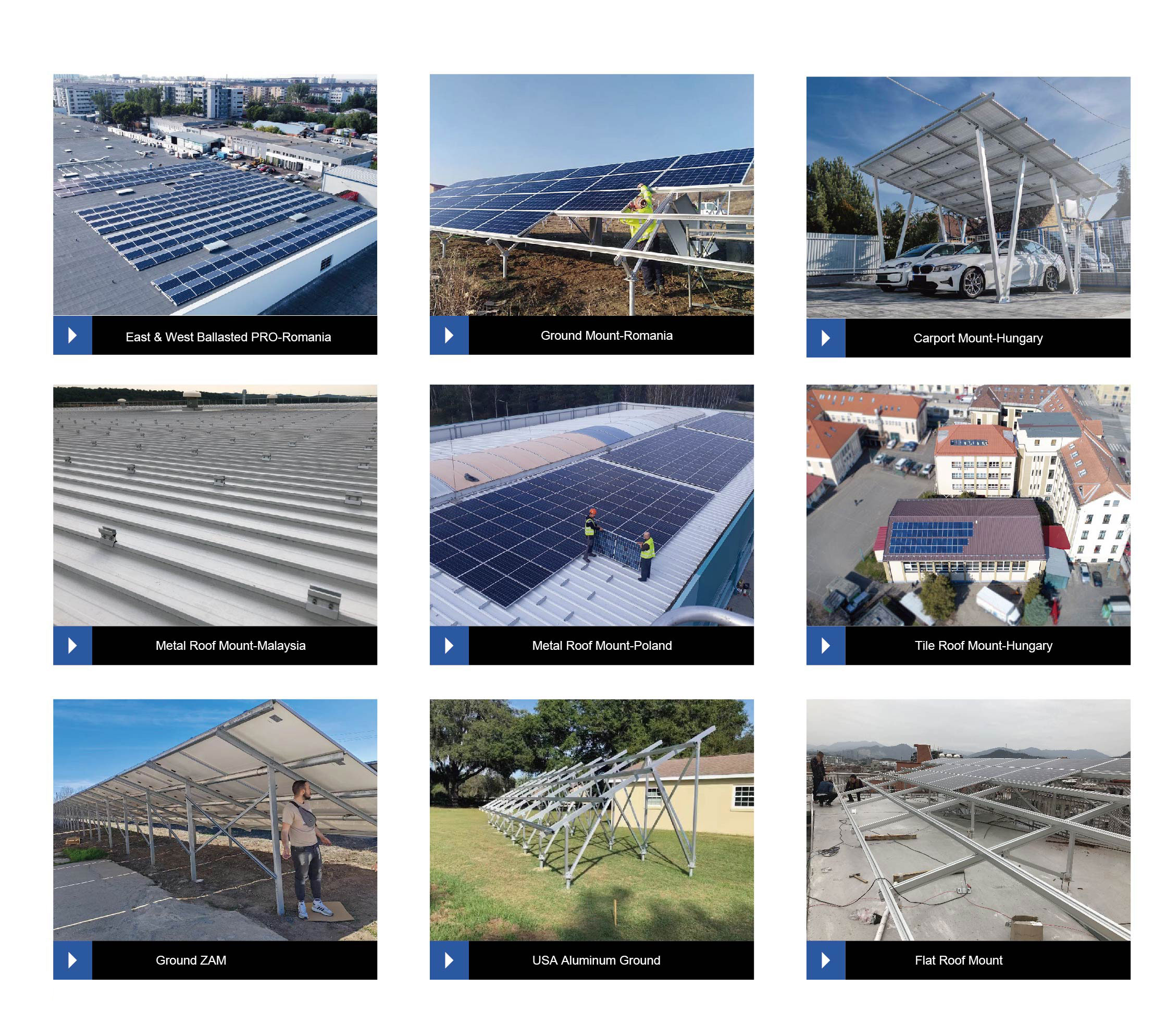

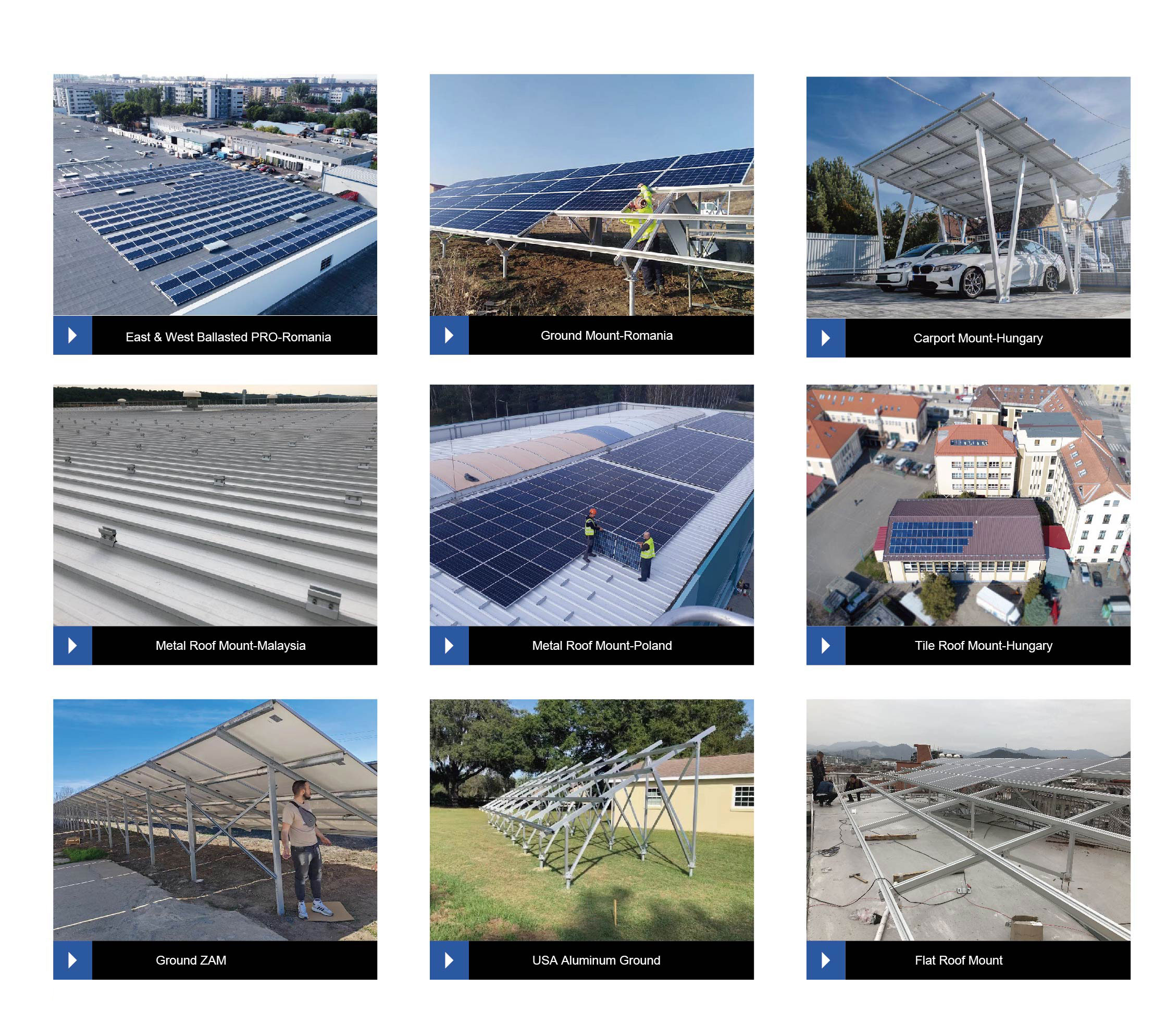

Our company has successfully completed solar racking installation cases in many countries around the world, winning high praise from customers and partners.

These projects cover the challenges of different regions, different climate conditions and different needs, fully demonstrating our excellent strength in solar racking design, installation and technical services. Our global success stories not only prove the high quality and stability of our products, but also demonstrate our strong commitment to promoting green energy and contributing to sustainable development.

In the future, we will continue to uphold innovation and excellence, provide more efficient and environmentally friendly solar support solutions for our global customers, and work together towards a better tomorrow of clean energy.

Our company has successfully completed solar racking installation cases in many countries around the world, winning high praise from customers and partners.

These projects cover the challenges of different regions, different climate conditions and different needs, fully demonstrating our excellent strength in solar racking design, installation and technical services. Our global success stories not only prove the high quality and stability of our products, but also demonstrate our strong commitment to promoting green energy and contributing to sustainable development.

In the future, we will continue to uphold innovation and excellence, provide more efficient and environmentally friendly solar support solutions for our global customers, and work together towards a better tomorrow of clean energy.

+8618030291681

Telephone

+86-15260817211